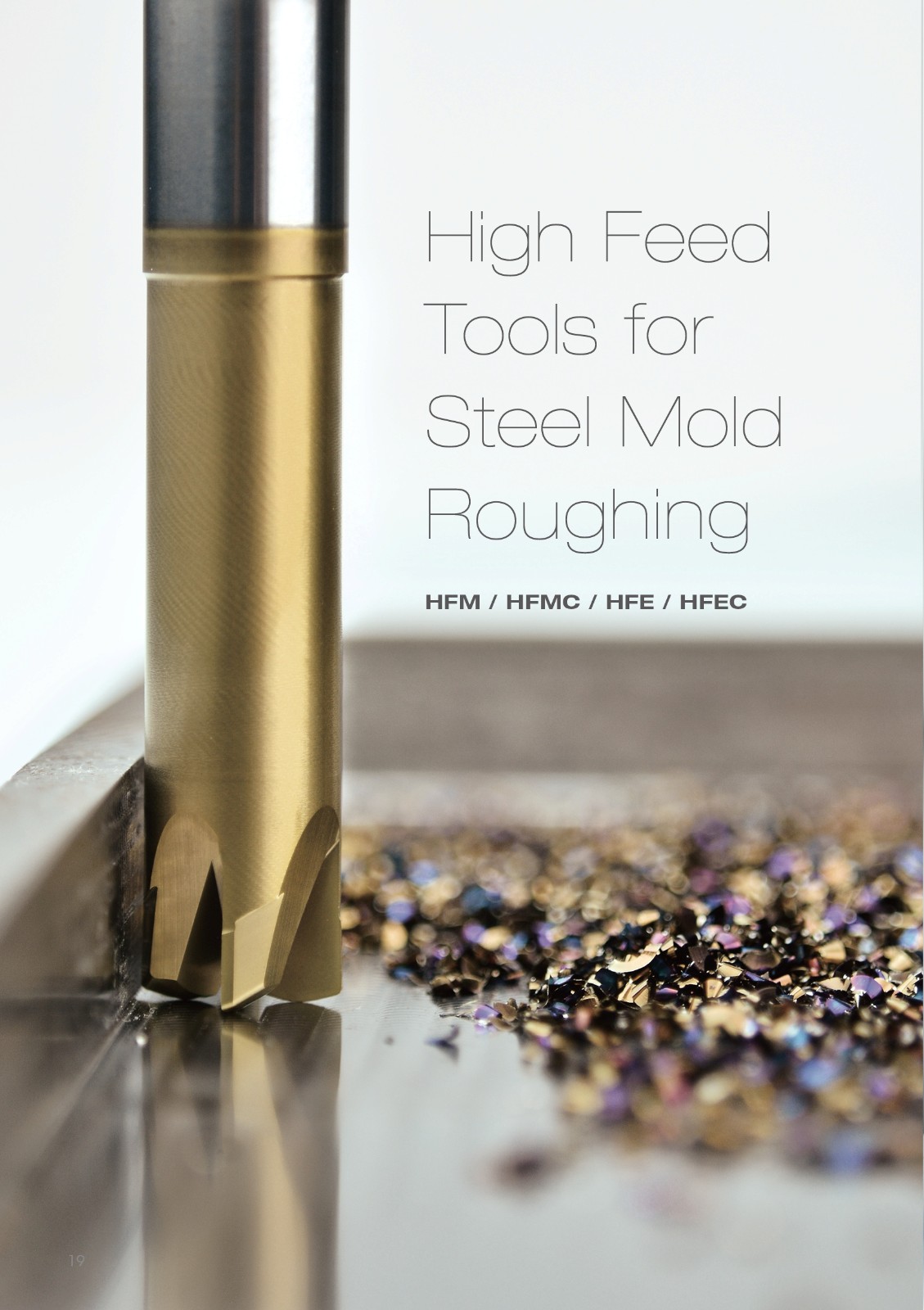

IDI high feed tool is the best choice when you need to remove your mold stock quickly. Specially designed geometry for small depth of cut, large cutting width and high feed rate, IDI high feed tools provide highly efficient roughing process and leave smooth stock for semi-finishing and finishing.

High lead angle conducts cutting force axially allows high overhang. When milling deep cavities, a typical 5-8 times overhang of diameter has never been a problem. Shallow depth of cut and high feed prepares the mold blank ready for semi-finishing and finishing. There is almost no need for residue stock roughing.

Large taper angle avoid interference with vertical walls.

Multilayer nanocomposite coating ensures high heat and wear resistance.

IDI high feed tools are coated with multilayer layers. Different elements and coating structure in different layers provide better protection in many ways. The first layer ensures good adhesion. The second layer provides high wear resistance while the upper layer provides good lubrication during cutting.

Special flute geometry and pretreated cutting edged lead to long tool life.

Optimal number of flutes for different sizes (from 2mm to 12mm), and wide space ensure fast chip evacuation during high feed and hence keep the tool from re-cutting the hot chips. Pretreated and rounded flute edge ensures the cutting edges wear at steady rate instead of chipping and breaking.

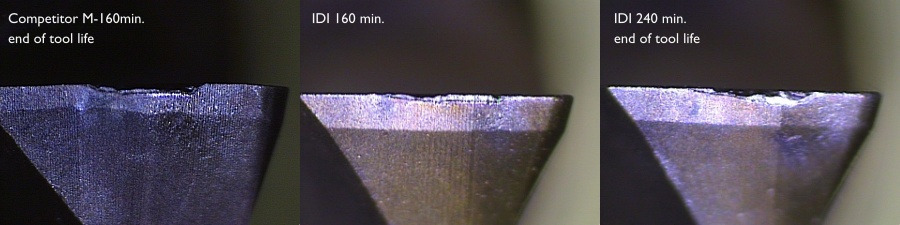

Cutting test:

Tool: HFM6-4-4-25-75

Material: 1.2344 HRC53

S7000, F4572mm/min.

ap 0.2mm, ae 55%

For small to medium-sized die and molds, HRC48-62, we have the right tool for you! From 1.5mm 2-flute to 1/2” (12.7mm) 4-flute, you can always find what you need for your high efficient roughing process. Above that, you can go directly into semi-finishing without worrying about the big serrations after roughing.