Edge preparation and polishing

BackEdge preparation has been a popular way for improving tool performance for many years. A good-processed edge preparation will smooth the flute edges, minimize mini- fractures, improving ground surface roughness, enhance coating adhesion and even the stress at the flute edge during machining. All these effects have the same final result: longer tool life, higher machining efficiency, better cut surface.

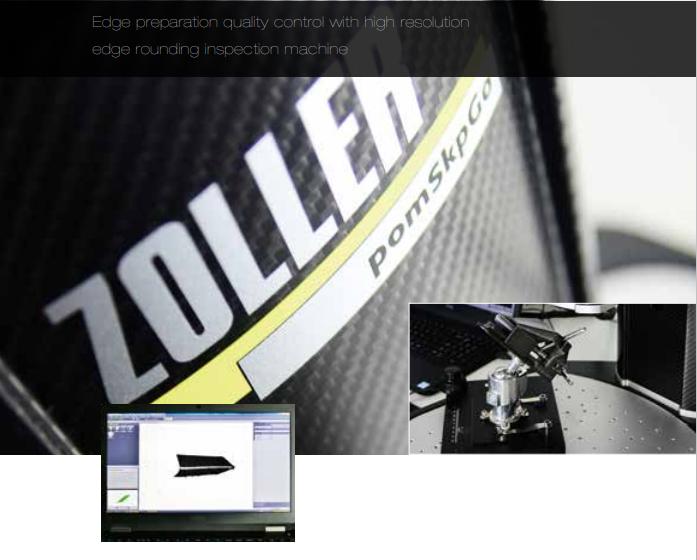

However, how to maintain a good edge preparation process and keep the same quality from batches to batches is an important topic. Without proper metrology methods, edge preparation control is not possible.

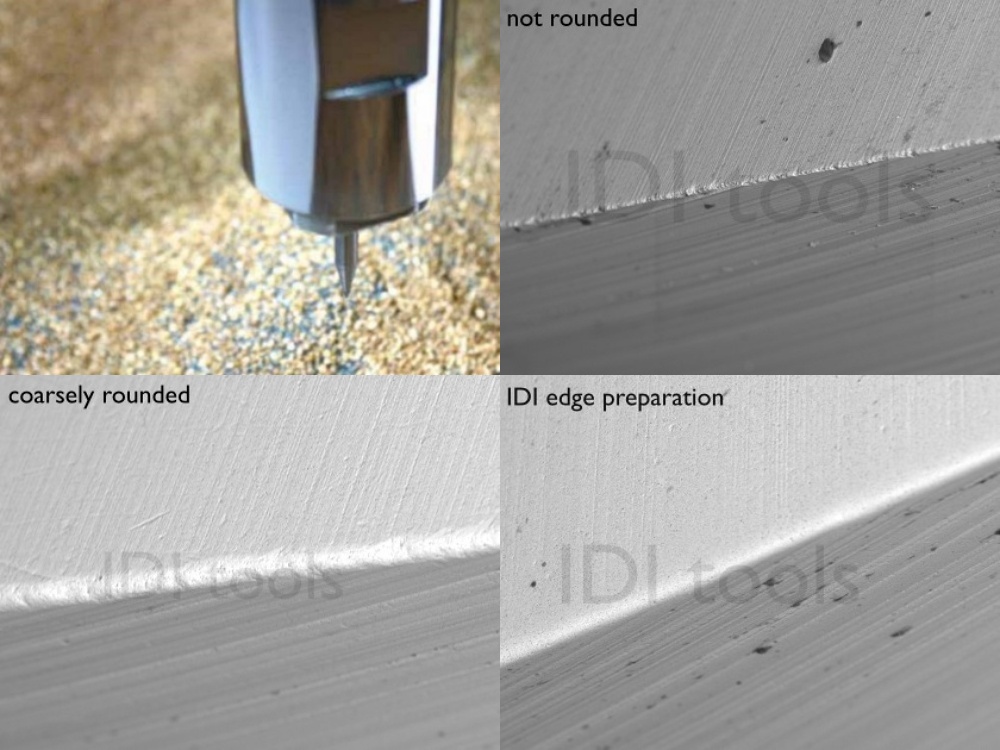

Below is a comparation of different edge rounding results.

In general, tool makers try to control several main processing parameters to maintain stable results. Take drag finishing for example: media type, submerged depth, rotating direction/speed and processing time are the main parameters that one may assume that control the edge preparation result. However, without actually seeing it and measuring it, other parameters may affect the rounded edge and customers may get totally different tool performance. These parameters, for example, humidity of the media, sharpness of the media, lubricant oil in the media, extrusion length of the tools, may not be so obvious but play an important way. The same processing condition may get different results a few months later.

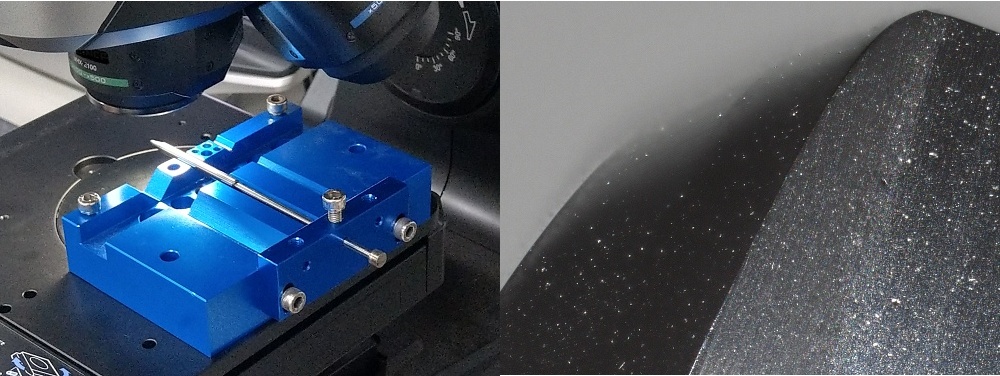

In IDI, we use state-of-the-art microscopes and edge radius measuring machine to control and monitor edge rounding quality. The rounded tool will not only perform best in development time but also maintain the same performance in mass production.

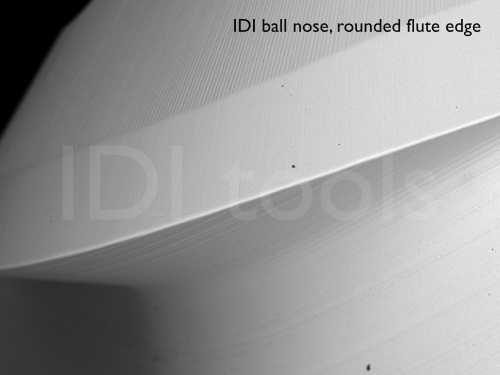

A good edge rounding process should smooth the flute edge and maintain accurate rounded radius from time to time. The result is shown as below:

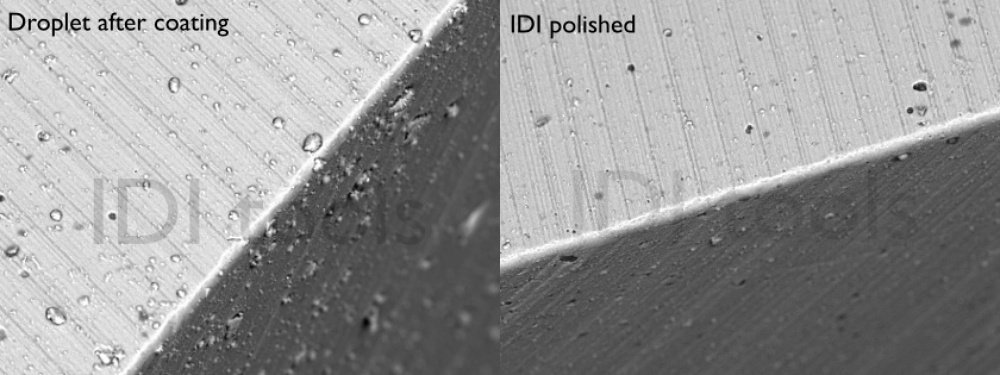

The same principle is valid in polishing droplets after coating.

Below is the result:

Edge rounding and polishing is not a new process in tool making. However, keeping the same quality from time to time is the key of success. One should focus more on metrology methods rather than just buying a machine and claim the capability of doing it.